Kunshan Janbo Electromechanical Co., Ltd.

Fax: 0512-57711608

Contact: Mr. Cao

Mobile: +86 15950939002

Mobile phone: +86 15895657606

Postal Code: 215300

Website: www.wodems.com

Address: No. 8, Nanhe Road, Development Zone, Kunshan City, Jiangsu Province

Product description

Features:

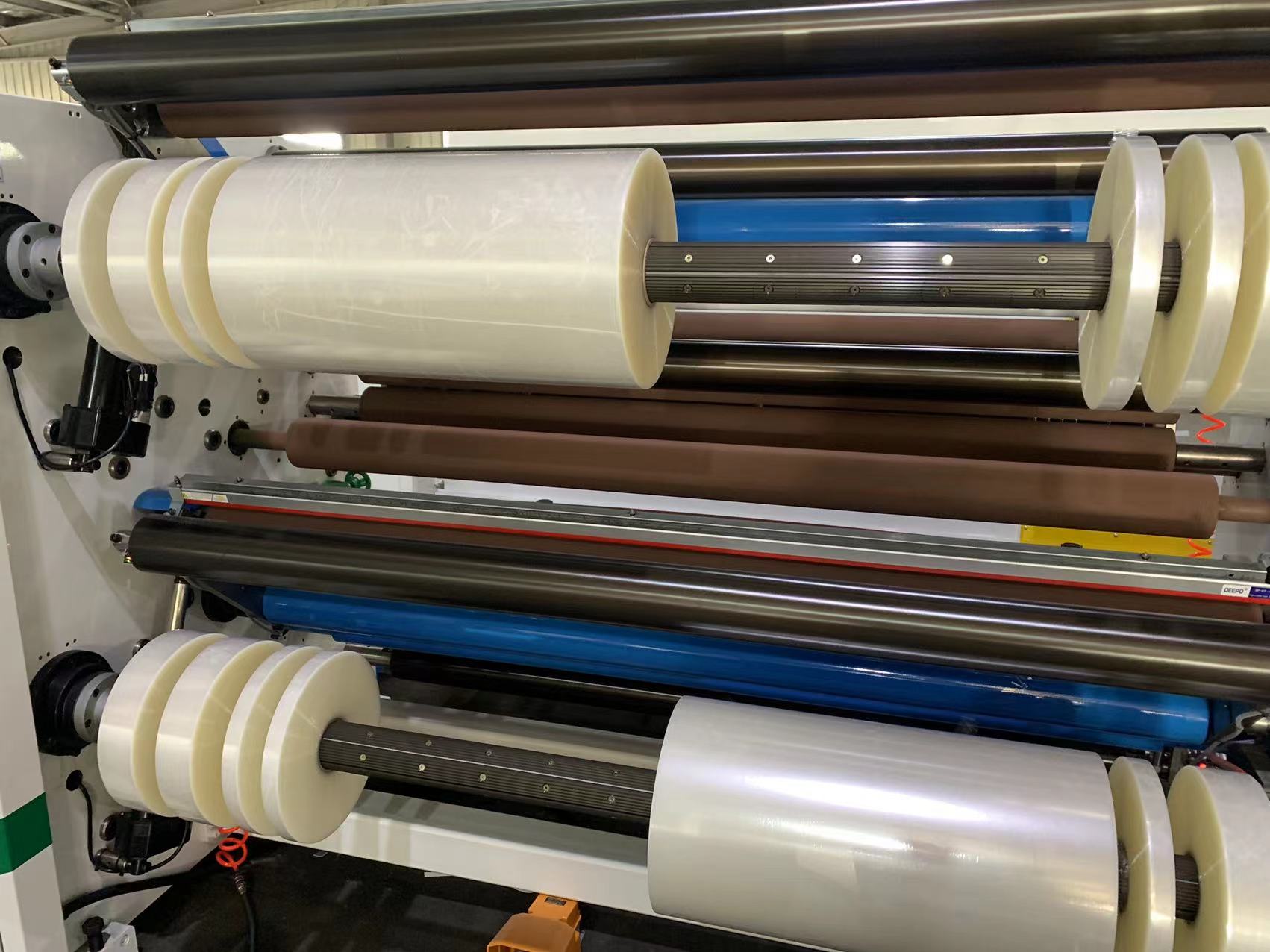

All kinds of tape and other materials rewind.

Specifications:

*Z large winding diameter: 350mm

* Core diameter: 1.5 "-3"

* Manufacturing width: 1.3M-1.6M

*Z Large feeding diameter: 800mm

*Z small slitting width: special for rewinding

* Mechanical Z High speed: 120M/Min

Introduction of equipment:

Main transmission part: AC motor with inverter as the material to transmit power, acceleration and deceleration stable and fast. The tension inverter is used to control the AC motor conveying tension, and the torque is fully automatic rebound control when the winding tension changes in diameter.

Part of the winding machine: the winding method is the center and the surface, and the application can be freely selected when rewinding different materials. The winding gas pressure shaft is automatically inflated and deflated, and the winding is automatically changed after the winding is completed.

Motor control part: The operation interface of the winder adopts an LCD touch screen, which can directly set various winding conditions and operating conditions on the screen. The control part uses a programmable controller for mechanical action control, and has a self-testing system. When the machine fails, it can diagnose the fault cause by itself.

Auxiliary discharge device: the winding machine material is rolled out through the surface press wheel, which can make the material smoother and reduce noise.

Auxiliary pulling device: The winding machine material can be rolled out through the motor to save pulling time and reduce material loss.

Basic discharge form: connected discharge stand, easy to operate, small footprint.

Optional equipment:

1. Auxiliary feeding of raw materials: The use of hydraulic power, suitable for the workshop without driving, can save manpower and shorten the loading and unloading time.

2. Automatic labeling device: After the rewinding machine reaches the set length, it automatically slows down the labeling to speed up the production speed, and the length can be freely set (the rubber face can be equipped with the model).

3. Discharge department noise reduction cover: reduce the noise generated when the material is rolled out and improve the quality and safety of the working environment.